Why Waterproof Cement Board Before Tiling?

Did you realize that over 70% of bathroom makeover mishaps are rooted in poor waterproofing?

Waterproofing cement boards before tiling is crucial to prevent moisture damage and mold growth, ensuring the longevity and integrity of your tiled surfaces. It is advisable to use products like RedGard to waterproof cement board surfaces effectively.

Yet, the quandary remains: how does one pinpoint the appropriate waterproofing technique, and which practices should be embraced? Remain with us as we traverse the methods that elevate your bathroom makeover from acceptable to extraordinary.

However, the question persists: How can one identify the proper waterproofing technique and determine which practices to adopt? We show you the methods that elevate your bathroom makeover from ordinary to exceptional.

Importance of Waterproofing

Ensuring the impermeability of your cement board before affixing tiles is paramount for averting moisture-induced harm and the propagation of mold within shower environments. When installing tiled barriers within zones susceptible to dampness, it’s imperative to ascertain the complete watertightness of your cement board. This precaution not merely aids in preserving the wall’s structural integrity but also wards off leakage that could culminate in expensive rectifications. Verily, absent adequate impervious measures, the resilience and longevity of your tile work stand jeopardized. The underlayer beneath the tiling necessitates a shield against the ingress of water, which could otherwise instigate the degradation of materials over time.

Opting for a dependable waterproofing agent such as Redgard build a defensive barrier that protects your tiled barriers from moisture. This procedure transcends the mere application of a sealant coat; it demands meticulousness, encompassing the sealing of board seams and the encompassing application of waterproof sealants. Overlooking the necessity to render your cement board watertight can precipitate the disintegration of not solely the surface but the entire wall edifice. By dedicating time to render your cement board impervious, you’re fortifying the future of your shower space, ensuring its enduring freedom from mold, structural integrity, and aesthetic appeal for forthcoming years.

Preparation Steps

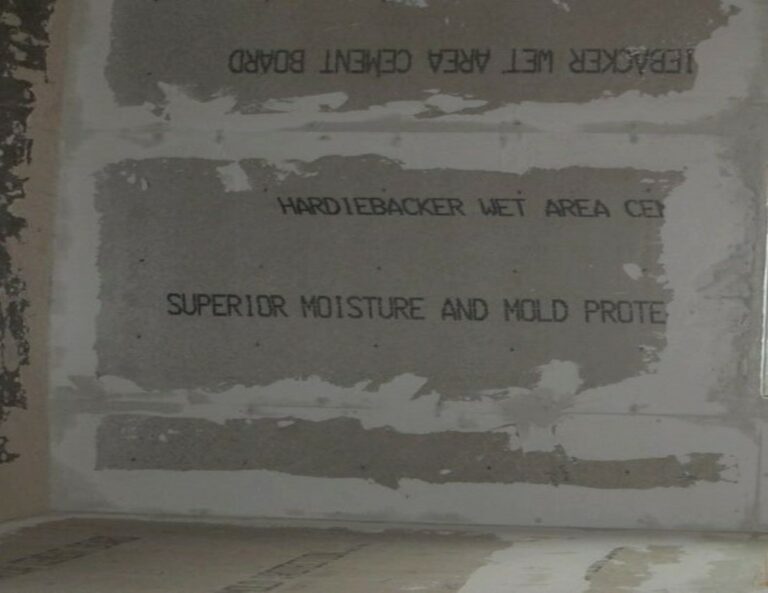

Embarking on the journey of waterproofing your shower necessitates meticulous groundwork, particularly with installing a cement backer board to furnish a robust foundation for tiling. This endeavor is paramount for ensuring the longevity of your waterproof cement board amidst the daily exposure to moisture. Commence by gauging the dimensions of your shower enclosure to ascertain the requisite volume of cement backer board. Employ a utility knife or saw for trimming the boards to the desired measurements, with acute precision required for circumventing any plumbing fixtures using hole saws to ensure an impeccable fit.

Proceed to affix the cement backer board to the wall studs utilizing cement board screws, distributed at intervals recommended for optimal endurance. Should you confront disparities in evenness between the backer board and pre-existing walls, shimming is advised to attain a uniform surface. This preparatory action is vital for a seamless adhesion of the thinset mortar and tiles.

Concluding, isolating the tub and spreading plastic sheeting is wise to intercept any debris from the thinset mortar and liquid waterproofing membrane application. Such preparatory measures are indispensable for facilitating a streamlined waterproofing endeavor and achieving a flawless finish within your shower domain.

Applying Waterproof Membranes

After preparing the surface meticulously, it’s paramount to coat it with a moisture-repelling layer, such as RedGard, to forge a barrier against dampness atop the cement board. This procedure is important for areas susceptible to water exposure, notably showers. RedGard, through its liquid application, solidifies into an impermeable seal, thwarting moisture from invading the cement board—a pivotal measure to avert water damage and the proliferation of mold beneath your ceramic tile.

Achieving unassailable waterproofing necessitates a singular application and a duo of membrane layers. The initial application serves as the primary blockade, while the subsequent layer bolsters this defense, affording an augmented safeguard against moisture ingress. This layered approach is indispensable in regions perennially in contact with water. The aim is to confine water to the tile surface, facilitating its evaporation or drainage rather than permitting infiltration to the cement board where it could wreak havoc or foster mold. A diligent application of these two layers lays a robust groundwork for your ceramic tile setup, promising an enduring shower.

Drying and Inspection

Upon application of the subsequent coating of RedGard, an imperative ensues to allow the waterproofing agent a curing duration of no less than a day before embarking on the tiling process. The importance of this drying interval can’t be overstated for the RedGard to properly adhere and meld with the cement board, establishing a robust, impervious barrier beneath the tiles. Hastening through this phase compromises the enduring resilience of your tilework.

Following the requisite curing span, a meticulous examination is warranted. Begin by scrutinizing the cement board’s expanse for any oversight or thinly applied sections of RedGard. Such oversights pose a risk of moisture infiltration if neglected. After the visual scrutiny, engage in a tactile evaluation across various sections of the board. The RedGard should be dry to the touch, forming a consistent, sturdy coating atop the cement board.

Should you encounter any portion of the RedGard waterproofing that hasn’t properly cured or exhibits flaws, dedicate time to rectify these issues immediately. A diligent examination at this juncture guarantees the integrity of your waterproofing, laying a solid foundation for the tile installation and fortifying your project against potential moisture-related complications.

Tiling Over Waterproofed Board

Overlaying tiles upon a waterproofed cementitious panel imbues your construction with robust, impervious foundations. This amplifies both the resilience and sanitation of your tile surfaces. Opting for waterproofing transcends mere tile application; it guarantees the substrate beneath remains impervious to moisture, drastically cutting down the likelihood of water-induced deterioration and clandestine mold proliferation behind your splendid tiles. This measure is imperative, particularly in locales with frequent moisture like showers and kitchen splashbacks.

Employing a waterproofing concoction such as RedGard onto the cementitious panel introduces an additional safeguard. This bulwark stands as your premier defense against moisture ingress, preserving the endurance of your tiling endeavor. Adhering meticulously to the concoction’s usage directives ensures comprehensive panel coverage for supreme moisture resistance.

After completing the waterproofing regimen, you can embark on the tiling venture with assurance, aware that the substrate is aptly fortified to endure the daily wear and tear. This simplifies the cleaning regimen of your tiled domains and sustains their aesthetic and structural integrity over time. Remember, a waterproofed cementitious panel is pivotal for a lasting, impervious, and visually appealing tile setup.

Frequently Asked Questions

Should You Waterproof Cement Board Before Tiling?

Safeguarding your cement board with a waterproof barrier before affixing tiles is advisable. This precautionary measure wards off the detrimental effects of moisture and the proliferation of fungi, thereby prolonging the resilience and impermeability of your shower partitions. Overlooking this pivotal step could compromise your tiled surfaces’ longevity and moisture resistance.

What Can I Use to Waterproof Cement Board?

Utilizing products akin to RedGard is advisable to ensure cement board surfaces’ impermeability. The application process involves layering it twice, with each stratum requiring complete desiccation before proceeding. Adherence to the guidelines provided by the manufacturer remains paramount to avert moisture ingress and to fortify the longevity of your endeavor.

How Do You Waterproof Cement Board Seams?

To ensure the seams of cement boards are impermeable, one should affix mesh tape designed for backer boards across all intersections and peripheries. Following this, employing a spatula and a mortar blend, meticulously coats these connections to establish a robust barrier against moisture ingress.

Can I Put Tile Directly on Cement Board?

Certainly, affixing tiles onto a cement backer board is feasible. This underlayment furnishes a robust platform conducive to the adherence of tiles, guaranteeing their durability over an extended period. Ensuring its meticulous installation is imperative for optimal outcomes.

Conclusion

Having completed your cement board’s waterproofing process, you’re primed for the tiling stage.

The dedication invested in sealing and priming the surface paves the way for a robust, impermeable shower area.

Adhering to the protocols for applying a waterproof barrier, such as RedGard, and observing the necessary drying and examination phases sets the foundation for a triumphant tiling endeavor.

Proceed with positioning those tiles! Your meticulously prepared base is poised to uphold a stunning, enduring facade.