How to Secure Cement Board

Securing the cement board correctly is crucial for your project’s success. I’ve seen my fair share of botched jobs due to improperly installed cement boards. It’s not just about getting it attached; it’s about ensuring it’s done right to avoid future headaches. In this quick guide, I’ll walk you through the steps and tips to install your cement board firmly and safely. We’ll cover everything from selecting the right screws to the proper technique for a solid, lasting hold. Let’s secure your cement board correctly – no shortcuts, just solid, practical advice.

Preparing the Substrate

Before installing the cement board, ensure the substrate is clean, level, and coated with a waterproofing membrane for optimal adhesion and moisture protection. Start by thoroughly preparing the substrate; sweep away all debris and dust for a pristine surface. If you encounter uneven areas, make sure to level them. A flat surface is crucial to prevent future cracking or instability.

Once the substrate is prepped, lay down plastic sheeting as an extra barrier against moisture. Then, it’s time to create a solid foundation: spread a uniform layer of mortar over the prepped area. This mortar bed is where you’ll embed your cement board. Remember, consistency is key when you apply the mortar—aim for a thickness that won’t slump or run.

Now you’re ready to install cement board. Position it on the wet mortar carefully and press down firmly to ensure strong adhesion. Check that it’s perfectly aligned and level because this is the basis for your tile work. Secure it further with screws, making sure they’re evenly spaced and driven flush with the board’s surface.

Cutting the Cement Board

After ensuring your substrate is level and properly prepared, you must trim the cement board to size using a jigsaw or circular saw with a carbide-grit blade for straight lines. If tackling intricate shapes or curves, you’ll also utilize a jigsaw to cut those areas, starting with a pilot hole drilled into the board for easier blade insertion.

For precise cuts, consider the following suggestions:

- Score the Cement Board: A utility knife can score the board before snapping it for cleaner edges.

- Secure the Board: Clamp your cement board to your work surface to prevent movement.

- Measure Twice, Cut Once: Always double-check your measurements to avoid wasted material.

- Safety First: Wear protective eyewear and a mask to guard against dust and debris.

- Smooth the Edges: After cutting, use a utility knife or a rasp to refine any rough edges.

Trimming cement boards can generate dust, so working in a well-ventilated area or outdoors is advisable.

With these steps, you’ll have precisely trimmed cement board ready for installation, ensuring a sturdy foundation for your tiling project.

Mixing Thinset Mortar

To ensure your cement board installation has a solid foundation, mix thin-set mortar to the consistency of peanut butter as per the manufacturer’s instructions. Start by grabbing your bag of thin-set and carefully reading the label. Familiarize yourself with the correct water-to-mix ratio for the product you’re using.

Pour the specified amount of clean water into a bucket. Then, while stirring with a drill equipped with a mixing paddle, gradually add the thinset mortar powder. This will help prevent lumps and ensure a homogeneous mixture. Thoroughly blend the thinset mortar until it reaches the desired peanut butter-like consistency. This is vital for achieving optimal adhesion when applying thinset to the subfloor.

After mixing, allow the thinset to sit for a few minutes as directed; this process is known as ‘slaking.’ Give it one final stir before beginning the thin-set application.

When it’s time to lay down the mortar, evenly spread it over the subfloor. This will create an ideal bed for your cement board, ensuring a strong and even base for your tiles to adhere to.

Laying Down Cement Boards

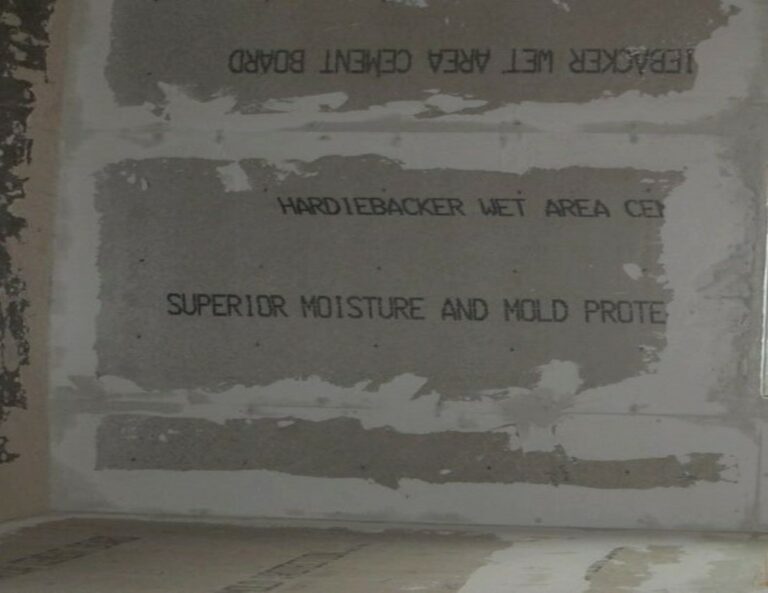

Ensure you have a sturdy work surface before laying down the cement boards, firmly pressing them into the thin-set mortar spread on the subfloor. Proper installation of cement board is vital for a long-lasting tile job. When handling cement backer board, remember that a strong bond with the subfloor is crucial to prevent movement and potential tile cracking in the future.

Here are a few tips to assist you with the process:

- Apply a thin layer of thin-set mortar on the subfloor using a notched trowel.

- Position the cement boards onto the thin-set, staggering the joints for added stability.

- Secure the boards with cement board screws every 8 to 12 inches.

- Avoid aligning cement board joints with subfloor joints.

- After laying down the boards, use fiberglass mesh tape and more thin-set to cover the seams.

It’s essential to ensure that the screws are driven in flush with the surface of the cement board to avoid any interference with tile placement.

Fastening Boards Securely

For a sturdy installation, you’ll need to secure the cement board firmly with screws spaced every 8 to 12 inches. Begin by ensuring you have the appropriate type of cement board screws, which are treated for moisture resistance and designed explicitly for this purpose. Carefully position each screw at least 1 inch away from the edges of the board to prevent cracking or damage. Utilize your drill to drive the screws in, ensuring they’re flush with the surface of the board for a seamless finish.

Once you have securely fastened the boards, it’s time to mix and apply thin-set mortar to the seams. This step is vital in creating a uniform, stable base for your tiles. After applying the thin-set, promptly embed fiberglass mesh tape over the joints. It’s crucial to work the tape into the mortar to ensure it adheres completely. These taped joints enhance strength and help prevent movement between the boards, which could damage the tiles in the future.

Taping and Mudding Joints

After ensuring the cement board is securely fastened with screws, it’s essential to apply fiberglass mesh tape over the seams to prevent future cracking. This step is crucial for maintaining the integrity of your walls or floors.

Here’s what you should do next:

- Utilize a drywall knife to apply a thin layer of mortar over the tape.

- Ensure the screws are flush with the surface before mudding to avoid any irregularities.

- Smooth the mortar with the knife, ensuring thorough taping and mudding of joints.

- Allow the mortar to dry according to the manufacturer’s instructions before proceeding.

- Lightly sand the area after the mortar dries to achieve a smooth, even surface.

Waterproofing Board Seams

Having secured the cement board with screws and mudded the joints, it’s crucial to protect the seams against moisture damage.

Choose a high-quality waterproofing membrane, which is essential for sealing the board seams. After mudding, apply a thin layer of thinset mortar over the seams. This layer helps ensure a strong bond and is an additional barrier against water penetration.

Next, cut the fiberglass mesh tape to length and carefully place it over the fresh thinset along the seams of the sheets of cement board. The mesh tape reinforces the joints and helps prevent future cracks. It’s important to embed the tape firmly into the mortar with a trowel, smoothing out any bubbles or wrinkles that might compromise the waterproofing.

Once the tape is in place, apply another layer of thinset. This secures the tape and creates a smooth surface for your tile. Make sure you have properly embedded and smoothed out the taped seams. This attention to detail will help create a watertight barrier, providing peace of mind that the area behind the tiles is well-protected from moisture.

Frequently Asked Questions

What Is the Best Way to Fasten Cement Board?

You’ll find using cement board screws every 8 to 12 inches the best way to fasten it. Don’t forget to tape the seams with fiberglass mesh tape and thinset for added strength.

What Can I Use to Stick Cement Board?

You’ll need thinset mortar and cement board screws to stick cement board. Spread the thinset with a notched trowel, lay the board, then fasten it with the screws for a secure hold.

What Adhesive Do I Use for Cement Board?

It would be best if you utilized a modified thinset mortar for cement board, ensuring it is impervious to water and possesses a formidable bond strength. It is advisable to steer clear of organic mastic. Always adhere to the instructions provided by the manufacturer to achieve optimal outcomes.

What Is the Best Way to Join Cement Board?

To join cement board, you’ll need to apply thin-set between the boards, press them together firmly, and fasten them with screws. Remember to tape and mud the joints for a smooth and seamless finish.

Let’s delve into the process of joining cement board. Firstly, apply a thin layer of thin-set between the boards. This innovative solution will maximize the bond between the boards and ensure a secure join.

Next, press the boards together firmly. This step is crucial to ensure a strong and durable bond. Doing so will unleash the cement board’s full potential and elevate your project’s overall quality.

Once the boards are pressed together, it’s time to fasten them with screws. Be sure to use top-notch screws that will securely hold the boards in place. This step is essential to ensure the long-term stability of the cement board.

Not only should you fasten the boards with screws, but it’s also important to tape and mud the joints. This step will provide a seamless and polished finish to your project. With the joints properly taped and mudded, your cement board will be ready to withstand the test of time.

Conclusion

You’ve accomplished it! Your base is ready, and the cement boards are trimmed, positioned, and secured with precision.

You’ve taped and applied joint compound to the seams, constructing a stronghold against moisture. With the seams waterproofed, your underlayment is impenetrable.

Now, step back and appreciate your craftsmanship; this sturdy foundation is prepared for the tile of your aspirations. It’s not just a job well done—it’s the groundwork for a space that will astonish for years.